They are everywhere.

If you haven’t already incorporated a gas powered generator into your off grid ham radio plans, you’re excluding a valuable resource. In the last decade or so, the variety and availability of generators has increased exponentially. Along with greater market penetration comes conflicting information and misunderstandings. Knowing the difference between conventional and inverter generators and what they can and cannot do is a great place to start.

Isn’t it all the same? No. conventional and inverter

No matter what type of generator one has, the final product of all of them is the same. Therefore, if you just want AC power and don’t care about the details, then any old generator will do. But you should care about the details. Issues such as fuel type & efficiency, noise, power stability & quality, and ease of maintenance are all important considerations. Thinking that “power is power” oversimplifies a topic that is a lot deeper than it seems at face value.

Conventional generators: The timeless standard.

Consumer-level conventional generators have been around for many decades. They are simple engines that turn an alternator and usually come in the familiar “open frame” format. The engines must turn the alternator at 3600 revolutions per minute. The math is simple. Each rotation is one AC cycle. If we want 60 cycles per second, then that means the alternator must maintain 3600 RPM. If the speed is too fast or too slow, the frequency will fluctuate accordingly.

A governor on the engine will hold the correct speed even as the load varies. This system is simple but somewhat temperamental, as any variance in the engine speed will effect the power output. Also, small engines constantly turning at high speed are quite noisy and more likely to malfunction. Unfortunately, manufacturers use very cheap stamped metal mufflers that can barely be called mufflers! This is so much of a problem that YouTube is full of DIY hacks to quiet down these generators. Many of the noise-abatement proposals are effective but are complicated and difficult to employ. In general, if you choose a conventional generator, a lot of noise is something you’ll just have to accept.

Pros:

- Inexpensive initial cost

- Simple design; easy maintenance

- Many types & varieties available

Cons:

- Poor fuel efficiency

- Engine running at constant high speed is more likely to break down

- Very noisy

Inverter generators: A step up, with a few conditions.

Inverter generators first appeared on the consumer market in the mid 1960s but did not become widely available until 1988 when Honda introduced the eu9i, which is the earliest ancestor of the hugely popular eu2000i in production today. Although considerably more expensive, inverters solved many of the problems of conventional generators.

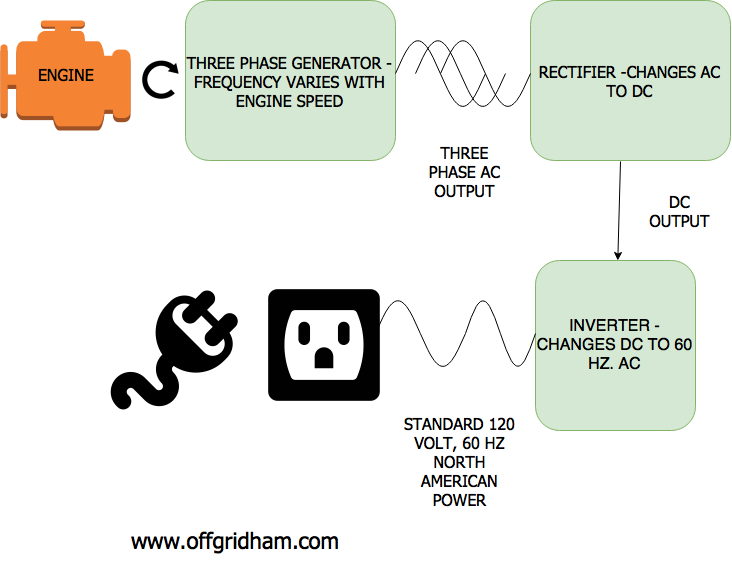

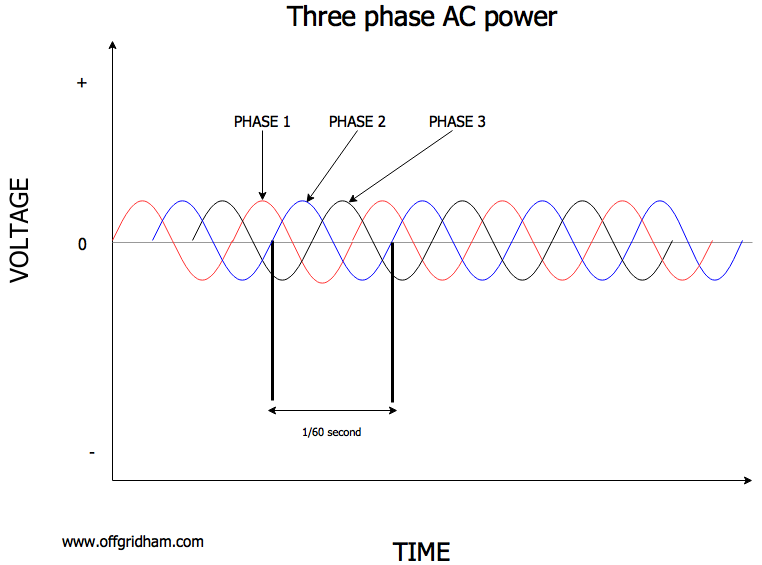

The principle of operation involves more steps than traditional 3600 RPM versions. An engine turns a three-phase alternator, the output of which in is run through a rectifier to convert AC to DC. The rectifier sends the DC into an inverter to create 60 cycle AC. You may be thinking, “why covert AC to DC just to change it back to AC again?” It’s a legitimate question with a logical answer. conventional and inverter

The AC-DC-AC conversion eliminates the need for the engine to run at a constant 3600 RPM. This means the engine can run at a high RPM when the load is heavy, and turn more slowly when the load is light. The output frequency of the alternator will vary as engine speed changes, but it does not effect the final output because the rectifier turns it into DC anyway. That DC then goes to the inverter, creating 60 cycle AC no matter how fast or slow the engine is going. The biggest benefits are much better fuel economy and quieter operation.

Another major difference with conventional generators is the use of a three phase alternator. We won’t get into the complex topic of three phase power here, but what you need to know right now is that it improves efficiency and three phase alternators take up less physical space and weight than a similar single phase alternator.

The major disadvantages of inverter generators is higher cost, higher theft risk, and more complex technology. The latter is not as bad as one might think. Over time technology has improved to the point that inverters and rectifiers, at least those used by the name-brand manufacturers, are very reliable. There are twenty year old inverter generators with hundreds and even thousands of hours on them out there still chugging along. I dare you to find a conventional 3600 RPM generator with that kind of longevity. Still, if your inverter generator does break down, repairs will likely be expensive and difficult.

Don’t get ripped off!

Finally, take seriously the risk of theft. Because inverter generators have a high “street value,” are comparatively small and light, and expensive, they are a favorite target for thieves. Take appropriate precautions to secure your generator. Likewise, if you find one for sale outside of normal sales channels for a crazy-low price, use some common sense!

Pros.

- Smaller and lighter than comparable conventional generators

- Quiet operation

- Fuel efficiency

Cons. conventional and inverter

- Higher initial cost- 2x-5x a comparable conventional generator

- Although very reliable, if it does break down it may be more difficult/more expensive to repair.

- High risk of theft.

The importance of load balancing; the reality of manufacturer power output claims.

Suppose you have a generator with a rated continuous output of 5000 watts. It does not matter if it’s conventional or inverter. You’ll notice that the panel has at a minimum two standard 120 volt household outlets and a 240 volt NEMA outlet of some type. Obviously, you are not going to pull 5000 watts from a single 120 volt household outlet, so how do you access the full capacity?

Common NEMA connectors found on larger generators: Two L-series twist lock plugs and two 5-15 common 120 volt plugs. OFF GRID HAM ORIGINAL PHOTO ®2017

The 5000 watt total is in essence two 2500 watt generators integrated together. Each of the household 120 volt outlets is wired to half of the generator and will top out at 1800-2400 watts each, depending on the design of the generator. The 240 volt output is the two 120 volt outputs combined. conventional and inverter

What this means is that to get full access to 5000 watts, you’ll have to balance your load across both sides of the generator. For example: You are running 1200 watts of radio equipment, lights, and other devices. You also want to power a 1500 watt electric heater. The total of 2700 watts exceeds the capacity of a single 120 volt outlet. What to do? Easy…plug the radios, lights, and appliances into one 120 volt outlet, and plug the heater by itself into the other outlet. Manufacturers wire the generator such that each outlet connects to different sides of the rotating coil, allowing the load to balance.

Not for amateurs!

Another load balancing method is make or buy an adapter that plugs into the 240 volt output and splits it into two 120 volt outputs. I made such an adapter for myself and it works great! Making an adapter is not complicated, but even a small wiring error can create a very serious safety hazard. Do not attempt a DIY 240-120 adapter unless you genuinely know what you are doing. Many retailers sell adapters for those not inclined to make their own.

Keep your fuel choices open.

In addition to standard automotive gas, conventional and inverter generators can also run on propane and natural gas. Some generators come from the factory with a bi- or tri- fuel option. For those that don’t, the average person can install an aftermarket fuel adapter, easily available on line.

Even if you don’t care about or think you’ll need the multi-fuel option, it’s a good idea to have it anyway. It gives you more flexibility in disaster/emergency situations when fuel may be scarce. The modest cost increase is worthwhile.

So which one is “best”?

If money is no object then an inverter generator with tri-fuel capability is the clear choice. For everyone else, it’s all a matter of priorities and tradeoffs. I personally have two conventional generators. Both work very well for their intended purpose. I’d like an inverter generator, but the cost of one that will suit my needs is, for now, beyond my means.

If you will need to operate life-supporting medical equipment, check with the manufacturer as they often have specific power requirements. With some acquired knowledge and understanding, you’ll find a generator that suits your needs.

Generators, a good topic. I have an all electric house and shop, with the exception of a propane range and BBQ. I am an ARES EC for our county, with a dual band station and HF trnaceiver in the house and a dual band in the shop.

Living in a rural area with usual outages, I had a Honda 6KW propane fired generator to power refrigerators, frezer and radios, etc. It was very loud, however it runs off a large propane tank. A couple of years ago I decided to install a 24KW Generac. This has been whell worth the investment. It takes about 3 seconds to come on once the PUD power is off. It will also switch off when PUD power is back on. To save full, I manually turn it off a bed time and leave it on manual control to save on fuel. The generator exercises itself on a reguar basis. I am very happy with this system and I know that I can always stay in radio contact.

Hi Karl, thanks for your comments. It sounds like you found a setup that works really well for you. I have a twist lock NEMA plug on my house and transfer switch. It requires me to manually connect and start the generator, then throw the transfer switch. It’s not automated, and I’m limited to the 5000 watt capacity of my portable conventional generator, but it is enough to supply basic household needs. Fortunately, the commercial power in my area is very reliable; I’ve had to go on the generator only a few times in 22 years, and even then it was never more than an hour or two.

Very good article Chris. Another thing to consider about generators is what type of output they have and what the intended use is. I’ve done some testing on power inverters but never had a variety of generators to check. These comments apply to power inverters as well.

Generator output can be pure sine wave, modified sine wave or square wave as I understand it.

Pure Sine Wave Generators: These generators produce a smooth, continuous wave and are typically used for sensitive electronic devices.

Modified Sine Wave Generators: These produce a wave that is similar to a sine wave but has a more squared-off shape. They are less complex and cheaper but may not be suitable for all devices, particularly those with sensitive electronics.

Square Wave Generators: These produce a waveform that alternates between two levels, creating a square shape. They are generally used for applications such as some types of motors or heating elements.

Hi Rick, thanks for your comment. I did not get into modified sine and square wave generators because these types of generators have not been produced for over thirty years. Some early (pre-1990) versions were modified sine wave, but nothing available today, as far as my research determines, uses this obsolete technology.

There are stand-alone modified sine wave inverters (not attached to a generator) currently on the market. I do not recommend them. In the past they were a more affordable compromise to (at the time) much more expensive pure sine wave inverters. Advancements in technology brought the price of pure sine wave models down and there is no longer a strong financial reason to buy a less desirable modified square wave inverter.

Square wave inverters are woefully obsolete technology and have not been produced for I would guess more than a decade. They still occasionally pop up on the used market. I would not recommend these either. The will work fine for resistive loads (such as an incandescent light), but are completely unacceptable for reactive loads, particularly electric motors, because electric motors depend on a complete 360 sine cycle to operate properly.

If you attempt to run an electric motor on square wave current, it may not run at all. If it does run, it will run more slowly, at a higher temperature, and sound different than it would on the proper power. You may get away with it for the short term, but that motor is going to fail much sooner.

I didn’t mean to turn this into a deep analysis of inverters, but I hope this clears a few things up. If you do a search on my website you’ll find several older articles that address these topics in detail.

Thanks for your comment and I hope you’ll tell your friends about Off Grid Ham.

Liked your article. Only missed you make a comparison chart and maker prices for each type.

Hi Carlos, thanks for your comment.

I considered a comparison chart and price list, but researching that and preparing the graphics would consume a lot of time. I am a real person and a real radio hobbyist, not artificial intelligence. Everything on this website is my original content unless otherwise cited.

Furthermore, there are already thousands of other resources detailing generator features and prices. In that regard, there isn’t much I can add to what’s already available.

Thanks again for stopping by Off Grid Ham. I hope you’ll cone back again soon.

I have a Briggs and Stratton inverter genny and have owned it for 15 years. It has been rock solid. Cost $1100 new. Had it in the shop for minor repairs among them the pull rope breaking and it not being accessible. No repair over $100

Hi Steve, I’m glad to hear you’ve had good luck with your Briggs. Proper routine maintenance will drastically stretch the service life of a generator.

Hours of run time will matter too. I have a generator that is 17 years old. It’s lasted this long because of low hours.