Moving electrons around.

Wire and electrical conductors are so fundamental that we use them without giving much thought to their importance. Conductors, or wire, are to electricity what pipes are to water. Without them, absolutely nothing happens. This time around we’re going to examine wire & conductors, their behavior, and how you can apply this knowledge to improving your radio operations.

What is an electrical conductor?

For a material to be a conductor, it has to be able to pass electrons easily. What this means on an atomic level is electrons in the outer orbit of an atom, called valence electrons, are easily broken free by an electric charge. The energized electrons can then “move” to neighboring atom. When this process is repeated over and over, useful electrical current is created.

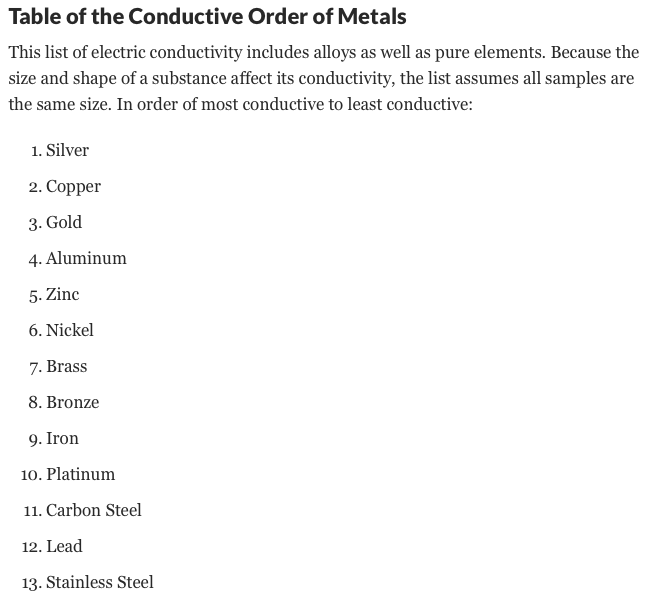

There is no formal criteria a material must meet in order to be considered a conductor. Conductors are usually classified based on their physical properties and for practical reasons. For example, silver is more conductive than copper. However, since silver is much more expensive than copper, copper is commonly used to make wire.

Another example is aluminum. Aluminum is less conductive than copper, but it’s also much lighter, less expensive, and less prone to corrosion. In weather-exposed applications where weight and density are critical, such as an antenna, aluminum is often a better choice.

By contrast, an insulator has very strongly bonded valence electrons; it does not want to let them go. No electron movement= no electricity flow. Every insulator will eventually fail if you shove enough voltage through it. The point at which an insulator fails is called breakdown voltage. Insulation on wire commonly used by radio amateurs has a breakdown voltage in the thousands of volts. Since hams seldom if ever see voltages that high, it’s not a concern.

The main point to remember is a material’s conductive properties are not the only important factor. If having the best conductor was the sole priority then everything would be wired with silver. At this writing silver is about $18.00 USD/oz (28g), copper is $0.23/oz, and aluminum is less than $0.07/oz. so it’s obvious why everyone uses copper and aluminum!

Considerations for copper wire.

What you can expect from copper depends on several factors. The size (gauge) of the wire, length, and type of current (AC or DC) are the main drivers of how copper wire will perform. To a lesser extent, temperature also has an effect.

As conductive as copper is, amateurs nonetheless need to take its resistance into consideration when planning projects. Particularly when used with DC current, copper wire can introduce substantial power losses.

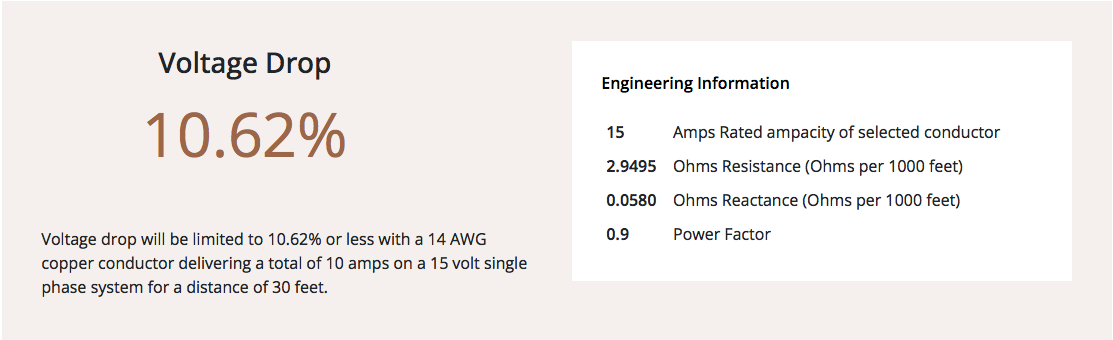

Example: You have a 12 volt solar panel system that produces 10 amps. The wire run will be 30 feet. Since you have a lot of 14 gauge wire leftover from a home brew antenna, you’re going to use that on this new project. Will it work? What can you expect? Here are the results from an online calculator:

We used 15 volts for this calculation because remember: A solar panel will always produce more voltage than its published rating. It looks like you’re going to drop 10.63% or 1.59 volts in the run from the solar panel. That’s before any other losses. Engineers consider a loss of 3% or less as acceptable. A 1.59 volt drop doesn’t sound like much, but if we apply the lessons from last month’s article about Ohm’s Law, that comes out a power loss of just under 16 watts.

As we’ve discussed many times before on Off Grid Ham, running off grid power is a delicate dance of tradeoffs. You’re always going to give in one area to gain in another. Is using that leftover wire worth throwing away over 10% of your energy? That’s for each individual to decide. If it were me, I’d be looking for a better option. “Better options” include: shortening the wire length, using a larger gauge wire, or boosting the voltage.

There are dozens of on line calculators that will help you figure out how any given type of wire will perform.

Solid vs. stranded wire.

Stranded and solid wire are not the same thing and do not perform the same way. A stranded wire may have the same total diameter of an identical gauge solid wire, but some of that cross-sectional space is air. This is why stranded wire has less current capacity than a solid wire of the same size. Also, because of those air gaps, stranded wire is more prone to corrosion. On the plus side, stranded wire is flexible and easy to push around tight turns and is a good pick for repetitive bending environments or coiling for transport.

You may have heard discussions over whether solid or stranded wire is “better”. It’s an empty argument. Which is better depends on the application, personal preferences, and availability. My wire antennas all use stranded wire because it’s easier to work with and has more flexibility in the strong storms common in my area. For home AC wiring. local building codes often have different rules for the different types of wire, or require one type or the other in certain situations. Generally, home AC wiring is solid.

Skin effect.

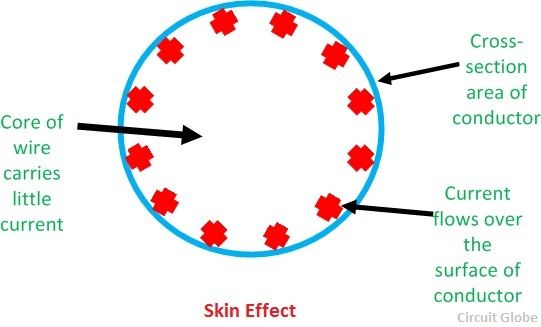

Skin effect applies only to AC current and is the phenomenon where the electron flow on the outer circumference of the wire is greater than it is in the center. Skin effect does not apply to DC. In DC current, the electron flow will be even across the entire diameter of the wire.

Off grid amateurs should not be concerned about skin effect. It can come into play when dealing with antenna feed lines and RF; for the purpose of electrical power for your equipment, simply know what it is to impress your friends and don’t worry about how it may effect your system.

Wire insulation: It matters!

So far we’ve talked a lot about wire and conductors, but the insulation around the conductor matters too. The wrong type of insulation can mean the difference between an application that runs reliably for years and one that fails after a few months or even weeks.

Polytetrafluoroethylene (PTFE) and Teflon are from the same fluoropolymer family. They have excellent resistance to oxidation and breaking down from UV radiation, can withstand both high and low temperatures, and can be directly buried. Either one would be a great choice. If it matters to you, Teflon is slightly more resistant to nuclear radiation than PTFE.

The problem with selecting wire insulation is that information is often lacking. Consumer packaging and websites often have vague subjective terms like “UV resistant” and “suitable for outdoors” without specifying the exact chemical makeup of the insulation. It would be worth your while to do some research and not just grab whatever is on sale on line or the local big box store.

Thermoplastic high heat nylon wire.

If you are an electrician or into home repairs/upgrades, you’ve probably heard of thermoplastic high heat nylon (THHN) wire.

It will withstand temperatures up to 194F/90C, is oil resistant, and meets NFPA-70 safety standards. THHN cannot be directly buried or used to convey high current in unprotected outdoor environments. It includes an outer nylon sheath to protect it from abrasion.

THHN is ok to use for outdoor antennas as those applications do not have the same safety concerns as AC or DC power. However, if used for an outdoor antenna the outer nylon sheath will eventually break down and peel off. For antennas this isn’t really a big deal but THHN should not be exposed if used to convey AC or DC power.

THHN is by far the most common type of wire used in North America for home and commercial electrical systems. You can buy it pretty much anywhere in many gauges, stranded and solid. If you have to choose only one type of wire, THHN would be the one. It is a must-have stock item for preppers/survivalists.

Don’t overthink this!

We’ve gone over the physical and electrical properties of various conductors. While it’s important to know how conductors work, it’s also important not to let yourself get lost in a technical maze. Operators with short wire runs (such as a portable setup) don’t need to sweat the details the way a home-based operator with long wire runs might. Basically, the more power you have and/or the longer your wire runs are, the more the issues we’ve discussed matter. If your off grid power system is not working as well as you think it should, take a critical look at the wire, connections, and conductors. The solution to your problem may not be as complex as it seems.

Great post. Thank you. I would like to make a request on a subject that all of us Hams run into. This is how to run your cables whether it is coax or cables from solar panels into your home or shack. In my case, I have a walk-out basement and I need to drill through cinder block. I guess with solar, you need to run metal conduit. I would like to make it as simple as possible.

Thanks again

Hello Richard, I’m glad you are enjoying Off Grid Ham. Most of the articles that appear on this website come from reader questions and suggestions. As far as I am aware, this is the only ham radio blog that takes requests! Your request is noted and in the suggestion box!

Thanks for your input.

Ah, the joys of electricity 🙂 I vividly remember one day in one of my electronics classes when my lab partner somehow fed way too much voltage into a Z-80 chip we were using for a controller. There was shrapnel everywhere. Bits were actually embedded in the ceiling tiles.

As you said, though, there’s no need to overthink it for most of us. The stuff we’re fiddling around with is generally relatively low voltages at low amperage and we don’t need to worry about things like insulation breakdown and wire overheating unless you’re working with a pretty hefty solar panel system and battery.

I leave the high voltage/amperage stuff alone. I’m a bit gun shy when it comes to that stuff. I won’t go poking around in my big old tube amplifier or things like that and I leave the house wiring to professional electricians. I nearly got electrocuted by a piece of equipment that was supposedly locked out back in the 1980s.

Hi Randall, the biggest challenge to writing this blog is finding a way to advance amateurs’ knowledge without getting lost in minutiae and nebulous concepts. This is, after all, a practical how-to website. The original version of this article had a discussion of the units of conductance (the Siemens, and it’s lost brother, mho). That section got chopped out during the editing process because it just seemed to go too far. I’ve been a professional communications electronics tech for nearly my entire career and the last time I dealt with Siemens and mhos was in engineering school. It’s interesting to me, but it’s not anything a ham would benefit from knowing.

So, I present concepts and terms up to the point of being challenging but I don’t want anyone to read too much into it. I’m personally very comfortable working with AC wiring and similar high power applications, but I don’t often deal with it here because I don’t want anyone to place themselves in an unsafe situation as a result of something they learned on my website.

As for your Z-80 meltdown, yeah, I’ve been there too. In my younger, less experienced years I’ve popped many capacitors and turned many resistors into charcoal. My very first job was at a business that sold instruments to measure fluid flow in pipes. Water and chemicals and other yuck would get in them and all sorts of stuff would fry. We would troubleshoot down to the component level and replace parts as needed, but in some cases it was cheaper and easier to replace an entire board. It’s all part of the learning experience; hopefully we all improve with time and practice.

I had similar experiences. I worked as a technician for a cash register company back in the 1990s and I preferred to just swap out entire sub assemblies and then repair them later at the shop. But I worked with a lot of equipment that was obsolete and had to carry along a full soldering station and a lot of test equipment in my van because we couldn’t get replacement parts. I swear some of that equipment was designed by idiots. Casio cash registers were the bane of my existence. I hated those things passionately. The receipt printers were junk, the communications was breathtakingly slow, the keyboards were fragile, they overheated constantly. I had one batch of keyboards where one of the ICs would literally blow up because the caps on the power supply would fail without warning… Sigh

Nice work to revive concepts and knowledge.

I appreciate the feedback, Carlos. Thanks for stopping by!

Pingback: Amateur Radio Weekly – Issue 252 • AmateurRadio.com